Vancouver, British Columbia – (March 2, 2022) – Battery Mineral Resources Corp. (TSXV: BMR) (OTCQB: BTRMF) ("Battery" or "BMR " or the "Company") is extremely pleased to announce encouraging drill core assay results from the recently completed phase 1 exploration and in-fill drill program at the Dalmacia target of the Punitaqui mine complex ('Punitaqui ") in Chile. Drilling continues at the Cinabrio Norte target where three diamond drills are in operation. The Punitaqui mine is slated for resumption of copper concentrate production in mid to late-2022.

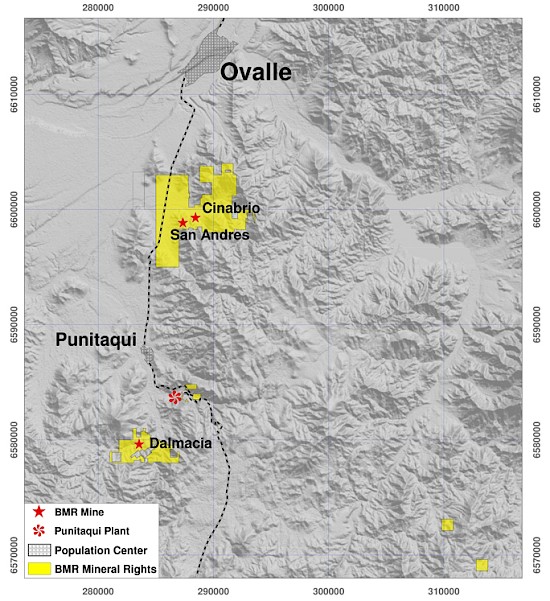

Dalmacia is located in the southern portion of Punitaqui about 6 kilometers ( "km ") south of the Punitaqui copper processing plant. The Dalmacia target has underground mining access, partially delineated mineralized zones and is targeted as a potential new source of ore feed to the Punitaqui plant (see Figure 1).

Highlights

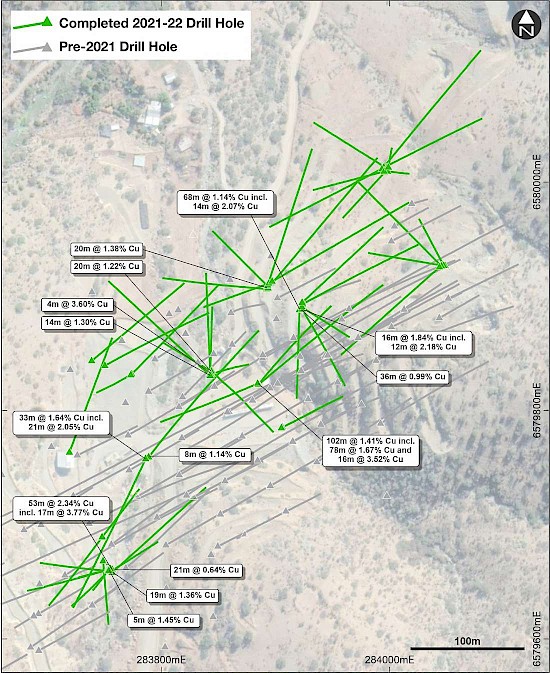

- At Dalmacia, phase 1 drilling has concluded for a total of 9,757 meters in 52 diamond drill holes. New assay results for the following Dalmacia drillholes include the following (see Table 1):

- DS-21-21: 53 meters ( "m ") at 2.34% Copper ( "Cu ") including 17m at 3.77% Cu

- DS-21-26: 33m at 1.64% Cu including 21m at 2.05% Cu

- DS-21-18: 68m at 1.14% Cu including 14m at 2.07% Cu

- DS-21-09: 16m at 1.84% Cu including 12m at 2.18% Cu

- DS-21-28: 20m at 1.38% Cu and 3m at 1.13% Cu

- DS-21-20: 14m at 1.30% Cu and 4m at 1.79% Cu

- DS-21-25: 20m at 1.22% Cu including 6m at 2.87% Cu and 6m at 1.46% Cu and 5m at 1.57% Cu

- DS-21-23A: 18m at 1.05% Cu and 19m at 1.36% Cu including 5m at 2.44% Cu

- DS-21-15: 8m at 1.14% Cu including 3m at 1.58% Cu

- DS-21-19: 36m at 0.99% Cu and 6m at 1.30% Cu

- DS-21-24: 21m at 0.64% Cu including 4m at 1.21% Cu

- DS-21-27: 5m at 1.45% Cu

- DS-21-22: 4m at 3.60% Cu and 3m at 1.12% Cu

- Significant copper mineralization was reported in 43 of the 52 holes in the phase 1 Dalmacia program.

- Detailed core logging and assaying is in progress for the remainder of the completed drillholes.

- Once final assays results are received, the new 3D geological model and assay database will form the basis of a resource estimate to be completed by JDS Energy & Mining Inc.

- Planning for both a follow-up infill program at Dalmacia and an exploration and infill drill test of the remaining 1,000m strike length at Dalmacia is underway.

Battery CEO Martin Kostuik states; "The conclusion of this phase of drilling at Dalmacia further confirm the high-grade nature of the copper mineralization at Dalmacia. Overall, the 2021-2022 Dalmacia North assay results are far better than expected with significant copper mineralization reported in 43 of the 52 holes of the program. These results clearly delineate high-grade copper grades over significant intervals and have greatly enhanced our understanding of the structural controls for the copper mineralization at Dalmacia. We look forward to future infill and step-out drilling along the 1,000m of strike length at Dalmacia not tested during the 2021-2022 phase 1 program.

Now, with the recently announced completion of the phase 1 drilling at our San Andres target and this announcement, we are two steps closer to providing the market with BMR's maiden resource statement for Punitaqui. Continued results like these strengthen our resolve for the planned restart of our former producing Punitaqui copper mine in Chile which gives our investors an opportunity to participate in a potentially significant re-rating in BMR's valuation as we transition from development to operations and positive cash flow. We look forward to providing further exciting updates for the remaining drill program in the coming weeks."

Dalmacia Drill Program

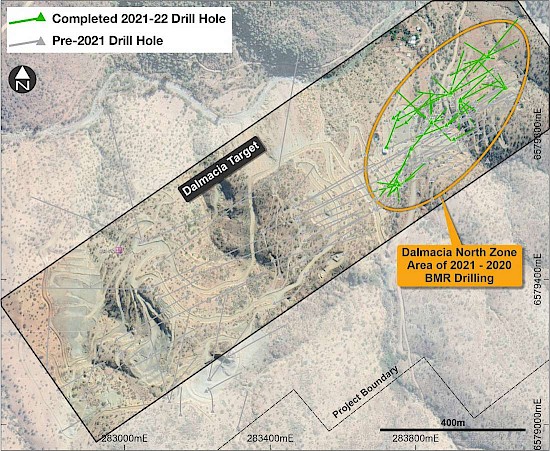

The Dalmacia target is in the southern portion of the Punitaqui area about 6km south of the Punitaqui processing plant (see Figure 1). Prior to the 2021 program, 229 drill holes (98 RC holes and 131 diamond core holes) had been drilled at Dalmacia for a total of 53,294m. Historic exploration drilling (1994-2020) at Dalmacia outlined a zone of oxide and sulphide copper mineralized striking northeast – southwest over a 1.6km strike length. The current BMR drilling is focused on the Dalmacia North zone (600m strike length) situated in the northeast portion of the Dalmacia target.

The geological setting of the Dalmacia target is different from the Cinabrio orebody which is located 20 kilometers to the north. Dalmacia is situated within a roof-pendant of volcanic rocks, with minor calcareous intercalations of Middle to Upper Jurassic age. This volcano-sedimentary complex is intruded by younger aged granites located in a reverse fault.

Copper-gold mineralization is related to regional structures and deformation zones, developed in the contacts between granite, sub-volcanic andesitic porphyry intrusives and volcano-sedimentary rocks. Controls on mineralization include small scale shear zones, intrusive contacts, vesicular andesites and alteration zones. These controls have different geometries leading to complex orebody shapes. High grade copper mineralization occurs in small high-grade pods which locally occur in clusters enveloped in low grade mineralization.

The upper portion of the Dalmacia target is accessed via a portal and an underground ramp with limited level development. The current Phase 1 drill program is designed to infill and confirm the continuity of mineralization between previous drilling and includes a series of step-out holes to test the potential adjacent to the main zone of copper-gold-silver mineralization as defined by historic drilling.

The recently completed phase 1 drill program consisted of 9,757m in 52 diamond core holes (see Figure 2 and Figure 3). Complete assay results were recently received for thirteen holes: DS-21-09, DS-21-15, DS-21-18 to DS-21-22, DS-21-23A and DS-21-24 to DS-21-28 (see Table 1). A summary of the targeting rationale and results for these recent drillholes follows below.

DS-21-09 was planned to test the down-dip and northern extent of copper mineralization intersected in two historic holes; DAL-20 that produced a 27m intercept of 0.91% Cu and DS-14-17 (27m at 1.84% Cu). The new hole did not intersect mineralization at the target depth and defined the northern limit of the mineralization intersected in DAL-20 and DS-14-17. In the upper part of DS-21-09 an intersection of 16m at 1.84% Cu from 98m including 12m at 2.18% Cu from 101m is interpreted to be an extension of the intersection of 32 m at 1.43% Cu, in DS-21-08. A narrow zone of 2m grading 1.35% Cu was intersected at depth from 234m.

DS-21-15 was designed to test both the down-dip and westward extent of the high-grade copper intersected in historic hole DAL-18 (21m at 2.56% Cu). The new hole successfully intercepted a 23m well-mineralized section, between 122m – 145m downhole, which hosted the same altered and mineralized vesicular ocoite as DAL-18. Significant intercepts in DS-21-15 are 8m at 1.14% Cu from 128m downhole including 3m at 1.36% Cu from 133m.

DS-21-18 was designed as an infill hole to test the upper high-grade intercept found in historic hole SD-04 (38m at 2.35% Cu from 24m). Hole DS-21-18 encouragingly encountered both oxide and sulphide copper mineralization from surface to 80m. The hole undercut the modelled plunging high-grade sulphide mineralization and intersected a broad intercept of oxide and sulfide copper (68m at 1.14% Cu) from 12m downhole (including 14m at 2.07% Cu oxides) and also a deeper sulphide interval of 8m at 1.50% Cu from 72m.

DS-21-19 was also drilled as an infill hole to follow-up a deeper intercept in historic hole SD-04 (28m grading 1.38% Cu). The hole intersected copper oxide mineralization from 12m – 45m transitioning to copper sulphides between 50m and 80m. Significant mineralized intercepts reported are 36m at 0.99% Cu from 12m downhole and 6m at 1.30% Cu from 66m.

DS-21-20 was planned as a 35m up-dip test of the extent of the lower intercept reported in BMR step-out hole DS-21-06 (95m at 0.78% Cu from 167m including 29m at 1.45% Cu, including a higher-grade interval of 14m at 2.44% Cu) and DS-21-14 (9m at 1.53% Cu). The new hole was successful as it intersected moderate to high grade mineralization from 56m to 90m and several zones of moderate chalcopyrite and bornite mineralization from 90m to 135m. Significant assay intervals include 14m at 1.30% Cu from 56m downhole including 8m at 1.27% Cu from 62m and 4m at 0.72% Cu from 116m and 4m at 1.79% Cu from 140m. The hole did not intersect significant mineralization at the target depth indicating that the mineralization intersected in drill holes DS-21-06 and DS-21-14 cuts out to the north.

DS-21-21 was planned to test the south extent of mineralization intersected in DS-14-13 (7m at 1.62% Cu). This hole successfully extended the mineralization to the south by intersecting a section of variably mineralized sandstone from 67.6m to 72m and well mineralized vesicular ocoite and andesite from 72m to 123m. Significant assay intervals included 53m at 2.34% Cu from 68m downhole including 45m at 2.57% Cu from 76m and including 17m at 3.77% Cu from 104m.

DS-21-22 was a step-out hole to test the up-dip extent of mineralization in DS-21-17(assays pending) and explore the area north of the current drilling. The hole cut a section consisting of moderate to high grade mineralization from 61m to 69m and weak to moderate mineralization from 69m to 148m. The lower part of the drill hole, from 182m to 202m, intersected a massive diorite intrusive with disseminated pyrite. Assay intercepts reported included 4m at 3.60% Cu from 60m downhole and 3m grading 1.12% Cu from 93m and a third intercept of 2m at 1.06% Cu from 128m.

DS-21-23A was planned to test north of the DS-21-16 intercepts (8m at 5.29% Cu and 8m at 3.53% Cu). The hole intersected several zones of moderate mineralization between 14m and 94m and a zone of high-grade mineralization from 94 to 102 meters. Zones of moderate to high grade copper deeper in the hole at 102m to 115m. Assay intervals confirmed the mineralization continued to the north and included 18m at 1.05% Cu from 39m downhole including 4m at 1.92% Cu and including 2m at 2.05% Cu as well as a second mineralized intercept of 19m at 1.36% Cu from 94m including 5m at 2.44% Cu from 97m and including 3m at 1.96% Cu from 110m.

DS-21-24 was designed as an infill hole to test down-dip and east of the DS-21-21 (53m at 2.34% Cu from 68m downhole including 45m at 2.57% Cu from 76m and including 17m at 3.77% Cu from 104m). The section drilled consisted of moderately mineralized sandstone from 77.8m to 81.2m and well mineralized vesicular ocoite from 81.2m to 118m.The hole intersected 21m at 0.64% Cu from 75m downhole including 4m at 1.21% Cu from 92m as well as a second intercept of 2m at 1.02% Cu from 115m.

DS-21-25 was drilled to test the southward extension of mineralization intersected in drillhole DS-21-06. The new hole successfully intersected 20m at 1.22% Cu from 52m downhole including 6m at 2.87% Cu from 52m. This mineralization is interpreted to be an extension of the intersection of 17m at 4.38% Cu, in historic hole SD-37. Deeper intersections of 6m at 1.46% Cu from 210m and 5m at 1.57% Cu from 224m are interpreted as southward down dip extensions of the mineralization intersected in drillhole DS-21-06 from 243 to 262 (19m at 1.10% Cu).

DS-21-26 was designed as an infill hole to test the dip direction of several zones of mineralization intersected in DS-21-07 (33m at 1.77% Cu, including intervals of 9.0m at 3.44% Cu) and DS-11-13 (22.9m at 1.14% Cu from 27.5m). The hole intersected moderately to strongly mineralized andesite from 77m to 104m that produced an assay interval of: 33m at 1.64% Cu from 72m downhole including 21m at 2.05% Cu from 77m. This mineralized interval is interpreted to be a down dip and southward projection of the mineralized interval in the upper part of DS-11-13.

DS-21-27 is an infill hole to test northern and deeper extent of mineralization intersected in DS-21-16 (8m at 5.29% Cu and 8m at 3.53% Cu). The hole cut a section of variably mineralized sandstone units from 60.4m to 64m and moderately mineralized vesicular ocoite from 64m to 84m. This intersection yielded a 5m interval grading 1.45% Cu from 68m downhole.

DS-21-28 was designed as an up-dip test of mineralization encountered in holes DS-21-06 (29m at 1.45% Cu from 183m and 19m at 1.10% Cu from 243m) and DS-21-14 (15m at 1.16% Cu from 145 and 9m at 1.53% Cu from 186). The intersections in DS-21-28 are interpreted to correlate with these intersections are 20m at 1.38% Cu intercept from 79m downhole and an interval of 3m at 1.13% Cu from 106m.

Significant BMR assay results received to date for the Dalmacia 2021 drilling include the following (see Table 2):

- DS-21-01: 23m at 1.16% Cu, including 13m at 1.56% Cu

- DS-21-02: 11m at 1.08% Cu, including 4m at 2.32% Cu

- DS-21-03: 15m at 1.01% Cu, including 4m at 2.47% Cu

- DS-21-04: 13m at 0.64% Cu including 2m at 1.24% Cu

- DS-21-05: 6m at 1.16% Cu

- DS-21-06: 32m grading 0.73% Cu including 16m at 1.15% Cu and 95m at 0.78% Cu including 29m at 1.45% Cu, including a higher-grade interval of 14m at 2.44% Cu

- DS-21-07: 33m at 1.77% Cu, including intervals of 9.0m at 3.44% Cu, and 7m at 2.54% Cu, and 10m at 0.84% Cu, and 6m at 2.19% Cu

- DS-21-08: 102m at 1.41% Cu including 78m at 1.67% Cu and 16m at 3.52% Cu

- DS-21-10: 2m at 2.40% Cu

- DS-21-11: 24m at 1.04% Cu including 4m at 1.60% Cu and an interval of 6m at 1.95% Cu

- DS-21-12: 11m at 0.82% Cu

- DS-21-13: 18m at 1.61% Cu, 12m at 2.13% Cu including 8m at 2.95% Cu and an interval of 5m at 3.26% Cu as well as an intercept of 7m at 1.87% Cu

- DS-21-14: 9m at 0.74% Cu including 4m at 1.03% Cu, 15m at 1.16% Cu including 7m at 1.44% Cu and an interval of 9m at 1.53% Cu and another intercept of 4m at 1.50% Cu

- DS-21-16: 8m at 5.29% Cu and 8m at 3.53% Cu

Table 1: New BMR-Dalmacia Target Significant Assays

|

Drillhole |

From |

To |

Sample |

Copper |

Silver |

Gold |

|

DS-21-09 |

89 |

91 |

2 |

0.88 |

1.3 |

- |

|

and |

98 |

114 |

16 |

1.84 |

0.5 |

- |

|

including |

101 |

113 |

12 |

2.18 |

0.6 |

- |

|

and |

234 |

236 |

2 |

1.35 |

0.5 |

- |

|

DS-21-15 |

128 |

136 |

8 |

1.14 |

1.2 |

0.023 |

|

including |

128 |

131 |

3 |

1.58 |

1.8 |

0.032 |

|

and |

133 |

136 |

3 |

1.36 |

1.3 |

0.025 |

|

DS-21-18 |

12 |

80 |

68 |

1.14 |

0.9 |

- |

|

including |

12 |

38 |

26 |

1.48 |

0.8 |

- |

|

including |

12 |

26 |

14 |

2.07 |

1 |

- |

|

and |

46 |

62 |

16 |

1.43 |

1.4 |

- |

|

and |

72 |

80 |

8 |

1.5 |

1.1 |

0.009 |

|

DS-21-19 |

12 |

48 |

36 |

0.99 |

0.3 |

- |

|

and |

66 |

72 |

6 |

1.3 |

0.7 |

- |

|

DS-21-20 |

56 |

70 |

14 |

1.3 |

0.7 |

- |

|

including |

62 |

70 |

8 |

1.27 |

0.9 |

0.521 |

|

and |

116 |

120 |

4 |

0.72 |

0.1 |

- |

|

and |

140 |

144 |

4 |

1.79 |

0.4 |

- |

|

DS-21-21 |

68 |

121 |

53 |

2.34 |

0.8 |

- |

|

including |

76 |

121 |

45 |

2.57 |

0.9 |

0.047 |

|

including |

104 |

121 |

17 |

3.77 |

0.8 |

0.1 |

|

DS-21-22 |

60 |

64 |

4 |

3.6 |

2.5 |

- |

|

and |

93 |

96 |

3 |

1.12 |

0.3 |

0.044 |

|

and |

128 |

130 |

2 |

1.06 |

0.1 |

- |

|

DS-21-23A |

39 |

57 |

18 |

1.05 |

0.3 |

- |

|

including |

40 |

44 |

4 |

1.92 |

0.9 |

0.069 |

|

including |

48 |

50 |

2 |

2.05 |

0.1 |

0.178 |

|

including |

55 |

57 |

2 |

1.54 |

0.1 |

0.065 |

|

and |

94 |

113 |

19 |

1.36 |

0.8 |

- |

|

including |

97 |

102 |

5 |

2.44 |

1.1 |

0.468 |

|

and |

110 |

113 |

3 |

1.96 |

1.7 |

0.112 |

|

DS-21-24 |

75 |

96 |

21 |

0.64 |

0.8 |

- |

|

including |

92 |

96 |

4 |

1.21 |

2.1 |

- |

|

and |

115 |

117 |

2 |

1.02 |

0.6 |

- |

|

DS-21-25 |

52 |

72 |

20 |

1.22 |

1.2 |

- |

|

including |

52 |

58 |

6 |

2.87 |

3.2 |

0.149 |

|

and |

210 |

216 |

6 |

1.46 |

0.3 |

- |

|

and |

224 |

229 |

5 |

1.57 |

0.1 |

- |

|

DS-21-26 |

72 |

105 |

33 |

1.64 |

4.8 |

- |

|

including |

77 |

98 |

21 |

2.05 |

6.9 |

- |

|

DS-21-27 |

68 |

73 |

5 |

1.45 |

0.7 |

- |

|

including |

68 |

72 |

4 |

1.64 |

0.8 |

0.005 |

|

DS-21-28 |

79 |

99 |

20 |

1.38 |

0.6 |

- |

|

and |

106 |

109 |

3 |

1.13 |

0.9 |

0.079 |

|

and |

121 |

123 |

2 |

1.15 |

0.1 |

0.079 |

Note: All intervals are downhole core lengths

Table 2: Earlier 2021 BMR - Dalmacia Target Significant Drill Assay Intervals

|

Drillhole |

From |

To |

Sample |

Copper |

Silver |

Gold |

|

DS-21-01 |

79 |

91 |

12 |

1.79 |

2.5 |

0.028 |

|

including |

80 |

88 |

8 |

2.44 |

3.2 |

0.035 |

|

and |

105 |

128 |

23 |

1.16 |

1.7 |

0.016 |

|

including |

115 |

128 |

13 |

1.56 |

2.1 |

0.024 |

|

including |

115 |

122 |

7 |

2.32 |

3.1 |

0.036 |

|

and |

137 |

139 |

2 |

1.06 |

0.7 |

0.03 |

|

and |

180 |

184 |

4 |

0.89 |

0.4 |

- |

|

and |

220 |

224.9 |

4.9 |

0.72 |

0.6 |

- |

|

DS-21-02 |

22 |

29 |

7 |

1.67 |

2.6 |

0.08 |

|

and |

64 |

74 |

10 |

1.03 |

2.1 |

- |

|

including |

64 |

67 |

3 |

1.49 |

2.3 |

- |

|

and |

71 |

73 |

2 |

2.34 |

5 |

- |

|

and |

99 |

106 |

7 |

2.58 |

2.7 |

- |

|

and |

177 |

188 |

11 |

1.08 |

0.9 |

0.08 |

|

including |

177 |

181 |

4 |

2.32 |

1.4 |

0.17 |

|

including |

177 |

180 |

3 |

2.9 |

1.7 |

0.22 |

|

DS-21-03 |

46 |

61 |

15 |

1.01 |

1.2 |

0.017 |

|

including |

46 |

50 |

4 |

2.47 |

3.1 |

0.05 |

|

DS-21-04 |

70 |

76 |

6 |

0.71 |

0.9 |

0.012 |

|

including |

72 |

76 |

4 |

0.87 |

1 |

0.01 |

|

and |

89 |

102 |

13 |

0.64 |

0.9 |

- |

|

including |

93 |

95 |

2 |

1.24 |

1.5 |

- |

|

DS-21-05 |

52 |

58 |

6 |

1.16 |

1.7 |

0.017 |

|

and |

131 |

132 |

1 |

1.81 |

0.4 |

0.695 |

|

and |

141 |

143 |

2 |

2.98 |

5 |

3.835 |

|

and |

155 |

156 |

1 |

3.22 |

2 |

- |

|

DS-21-06 |

37 |

69 |

32 |

0.73 |

0.5 |

- |

|

including |

37 |

53 |

16 |

1.15 |

0.6 |

0.06 |

|

including |

37 |

44 |

7 |

1.75 |

0.8 |

0.079 |

|

and |

112 |

115 |

3 |

2.14 |

0.6 |

0.03 |

|

and |

134 |

139 |

5 |

1.58 |

0.4 |

0.019 |

|

and |

167 |

262 |

95 |

0.78 |

0.5 |

- |

|

including |

167 |

170 |

3 |

1.84 |

0.8 |

0.096 |

|

and |

183 |

187 |

4 |

1.75 |

0.6 |

0.071 |

|

and |

19 |

262 |

65 |

0.93 |

0.5 |

- |

|

including |

197 |

211 |

14 |

2.44 |

0.7 |

0.039 |

|

and |

243 |

262 |

19 |

1.1 |

0.6 |

0.022 |

|

including |

243 |

251 |

8 |

1.88 |

0.7 |

0.029 |

|

and |

260 |

262 |

2 |

1.79 |

0.7 |

0.06 |

|

DS-21-07 |

24 |

57 |

33 |

1.77 |

1.5 |

0.052 |

|

including |

24 |

33 |

9 |

3.44 |

1.6 |

0.167 |

|

and |

39 |

46 |

7 |

2.54 |

3.5 |

0.02 |

|

and |

84 |

94 |

10 |

0.84 |

1.2 |

0.032 |

|

and |

176 |

182 |

6 |

2.19 |

0.4 |

- |

|

DS-21-08 |

48 |

150 |

102 |

1.41 |

1.2 |

- |

|

including |

48 |

126 |

78 |

1.67 |

1.4 |

- |

|

including |

48 |

64 |

16 |

3.52 |

4.5 |

0.017 |

|

DS-21-10 |

138 |

140 |

2 |

2.4 |

1 |

- |

|

DS-21-11 |

59 |

61 |

2 |

1.14 |

2 |

0.043 |

|

and |

78 |

102 |

24 |

1.04 |

0.5 |

- |

|

including |

78 |

88 |

10 |

1.06 |

0.5 |

- |

|

including |

78 |

82 |

4 |

1.6 |

0.4 |

- |

|

including |

86 |

88 |

2 |

1.78 |

1 |

- |

|

and |

96 |

102 |

6 |

1.95 |

0.4 |

- |

|

DS-21-12 |

116 |

121 |

5 |

0.62 |

1 |

- |

|

and |

143 |

145 |

2 |

0.95 |

1 |

- |

|

and |

161 |

172 |

11 |

0.82 |

0.5 |

- |

|

DS-21-13 |

44 |

62 |

18 |

1.61 |

0.7 |

0.01 |

|

and |

135 |

147 |

12 |

2.13 |

1.5 |

- |

|

including |

139 |

147 |

8 |

2.95 |

1.9 |

- |

|

and |

157 |

162 |

5 |

3.26 |

0.9 |

- |

|

and |

181 |

188 |

7 |

1.87 |

0.7 |

- |

|

DS-21-14 |

73 |

82 |

9 |

0.74 |

0.7 |

0.038 |

|

including |

78 |

82 |

4 |

1.03 |

0.7 |

0.05 |

|

and |

145 |

160 |

15 |

1.16 |

0.4 |

- |

|

including |

145 |

152 |

7 |

1.44 |

0.4 |

- |

|

and |

172 |

174 |

2 |

1.11 |

0.4 |

- |

|

and |

186 |

195 |

9 |

1.53 |

1.6 |

0.052 |

|

and |

205 |

209 |

4 |

1.5 |

0.4 |

0.24 |

|

DS-21-16 |

74 |

82 |

8 |

5.29 |

|

0.026 |

|

and |

102 |

110 |

8 |

3.53 |

|

0.065 |

Note: All intervals are downhole core lengths

Figure 1: Punitaqui Drill Target Location Map- Dalmacia 6 Kilometers South of the Punitaqui Copper Processing Plant

Figure 2: Dalmacia Target Map Drill Collar Plan

Figure 3: Dalmacia North Target Drill Collar Plan

Other Corporate Maters

Battery Mineral Resources Corp. wishes to announce that it has retained the services of Vancouver-based Mars Investor Relations Corp. ( "Mars "), a full-service investor relations and consulting services company focused on the junior mining sector. Under the terms of the engagement agreement (the "Agreement "), Battery Mineral Resources Corp. will compensate Mars $180,000 over the 12-month initial term of the Agreement and has granted Mars stock options (the "Options ") exercisable to acquire an aggregate of 200,000 common shares at a price of $0.65 per share until 90 days after the termination of the agreement. The Options shall vest quarterly over a period of 12 months, with 25% vesting each quarter. The Options and any shares issuable upon exercise thereof are subject to a hold period of four months and one day. In addition, Mars and or its affiliates currently hold zero securities of BMR, however Mars may from time to time acquire or dispose of securities of the Company through the market, privately or otherwise, as circumstances or market conditions warrant. Mars is at arm's length to Battery Mineral Resources Corp. and has no other relationship with Battery Mineral Resources Corp., except pursuant to the Agreement.

Quality Control

Sample preparation, analysis and security procedures applied on the BMR exploration projects is aligned with industry best practice. BMR has implemented protocols and procedures to ensure high quality collection and management of samples resulting in reliable exploration assay data. BMR has implemented formal analytical quality control monitoring for all field sampling and drilling programs by inserting blanks and certified reference materials into every sample sequence dispatched.

Sample preparation is performed ALS Global - Geochemistry Analytical Lab in La Serena, Chile and sample analyses by ALS in Lima, Peru. ALS analytical facilities are commercial laboratories and are independent from BMR. All BMR samples are collected and packaged by BMR staff and delivered upon receipt at the ALS Laboratory. Samples are logged in a sophisticated laboratory information management system for sample tracking, scheduling, quality control, and electronic reporting. Samples are dried then crushed to 70% < -2 millimeters and a riffle split of 250 grams is then pulverized to 85% of the material achieving a size of <75 microns. These prepared samples are then shipped to the ALS Laboratory in Lima Peru for analyses by the following methods:

- ME-ICP61: A high precision, multi-acid digest including Hydrofluoric, Nitric, Perchloric and Hydrochloric acids. Analysed by inductively coupled plasma ( "ICP ") mass spectrometry that produces results for 48 elements.

- ME-OG62: Aqua-Regia digest: Analysed by ICP-AES (Atomic Emission Spectrometry) or sometimes called optical emission spectrometry (ICP-OES) for elevated levels of Co, Cu, Ni and Ag.

Certified standards are inserted into sample batches by ALS. Blanks and duplicates are inserted within each analytical run. The blank is inserted at the beginning, certified standards are inserted at random intervals, and duplicates are analysed at the end of the batch.

Additional Information

Michael Schuler, Battery Mineral Resources Corp. Chile Exploration Manager, supervised the preparation of and approved the scientific and technical information in this press release pertaining to the Punitaqui Exploration Drill Program. Mr. Schuler is a qualified person as defined by National Instrument 43-101 - Standards of Disclosure for Mineral Projects.

About Battery Mineral Resources Corp.

A battery mineral company with high-quality assets providing shareholders exposure to the global mega-trend of electrification and focused on growth through cash-flow, exploration, and making acquisitions in the world's top mining jurisdictions. BMR is currently developing the Punitaqui Mining Complex and pursuing the potential near term resumption of operations for second half of 2022 at the prior producing Punitaqui copper-gold mine. The Punitaqui mine, operating as recently as April 2020, has typically produced 20 to 25 million lb. of copper in concentrate during its 9 plus year operating history and is located in the Coquimbo region of Chile.

BMR is engaged in the discovery, acquisition, and development of battery metals (cobalt, lithium, graphite, nickel and copper), in North and South America and South Korea with the intention of becoming a premier and sustainable supplier of battery minerals to the electrification marketplace. BMR is the largest mineral claim holder in the historic Gowganda Cobalt-Silver Camp, Canada and continues to pursue a focused program to build on the recently announced, +1-million-pound high grade cobalt resource at McAra by testing over 50 high-grade primary cobalt silver-nickel-copper targets. In addition, the Company owns 100% of ESI Energy Services, Inc., also known as Ozzie's, a mainline pipeline and renewable energy equipment rental and sales company with operations in Leduc, Alberta and Phoenix, Arizona. ESI, established in 1979, typically generates positive EBITDA in the range of C$4-$5 million and is poised for growth in 2022. For more information on the business of Ozzie's Pipeline Padder, see http://ozzies.com

For further information, please contact:

Battery Mineral Resources Corp.

Martin Kostuik

Phone: +1 (604) 229 3830

Email: info@bmrcorp.com

Neither the TSXV nor its Regulation Services Provider (as that term is defined in the policies of the TSXV) accepts responsibility for the adequacy or accuracy of this press release.

Forward Looking Statements

This news release includes certain "forward-looking statements " under applicable Canadian securities legislation. There can be no assurance that such statements will prove to be accurate, and actual results and future events could differ materially from those anticipated in such statements. Forward-looking statements reflect the beliefs, opinions and projections of the Company on the date the statements are made and are based upon a number of assumptions and estimates that, while considered reasonable by the Company, are inherently subject to significant business, economic, competitive, political and social uncertainties and contingencies. Many factors, both known and unknown, could cause actual results, performance, or achievements to be materially different from the results, performance or achievements that are or may be expressed or implied by such forward-looking statements and the parties have made assumptions and estimates based on or related to many of these factors. Such factors include, without limitation, the ability of the Company to obtain sufficient financing to complete exploration and development activities, the ability of the Company to complete the Debenture offering, risks related to share price and market conditions, the inherent risks involved in the mining, exploration and development of mineral properties, the ability of the Company to meet its anticipated development schedule, government regulation and fluctuating metal prices. Accordingly, readers should not place undue reliance on forward-looking statements. Battery undertakes no obligation to update publicly or otherwise revise any forward-looking statements contained herein, whether because of new information or future events or otherwise, except as may be required by law.