Guemam

Key Facts

Overview

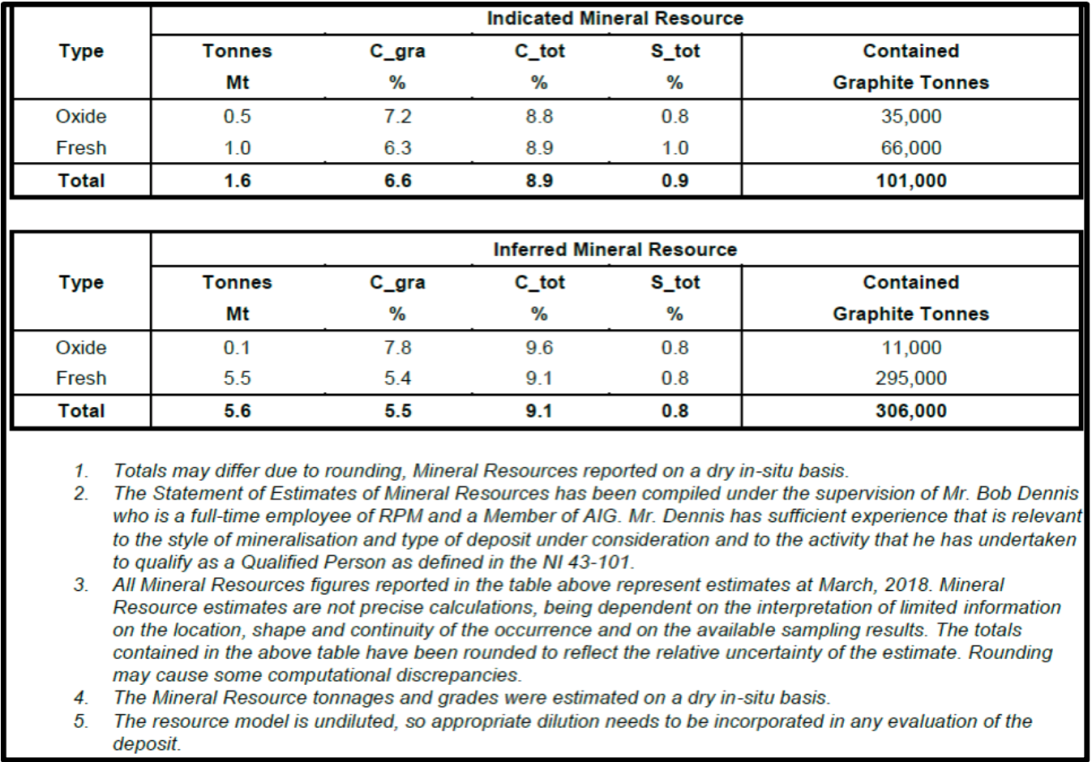

Guemam is located 20 kilometers from South Korea's second-largest lithium-ion battery factory and has a maiden NI 43-101 resource. Indicated mineral resources on the property stand at approximately 101-kilo tons containing 6.6 percent graphite grades.

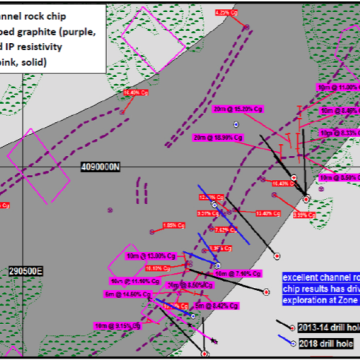

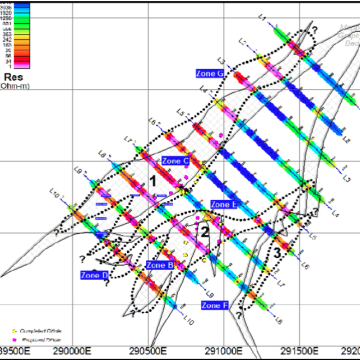

BMR in 2018 completed a 10-line IP survey that encompassed an area from the Target D in the southwest through Targets "B-C-E & F" in the central part of the zone and extending about 400m northeast of target G on the Northwest end of the known mineralised zone.

The survey clearly identified several new areas as potential graphite zones. The IP extended the potential strike length of graphite in Targets B & E, identified IP anomalies in Target G, found IP anomalies at mapped graphite horizons over a strike length of ~900m, outlined strong anomalies along strike in Target C, & identified a new trend 75m - 150m to the east of Target F.

- Best mineralisation hosted in Zones B and Zone E.

- Zone G appears more prospective than Zone F.

- Western side of Zone B has potential for shallow high-grade graphite

Low resistivity anomalies were identified under colluvium in the area between Zones B and E. The survey also extended the potential strike length of graphite at Targets B and E. Significant IP responses were identified at Target G. The anomalous responses mostly coincide with recently mapped graphite horizons and extend over a strike length of about 900m. At Target C the survey outlined stronger anomalies along strike from the current focus of attention. To the southeast at Target F; a potential graphitic trend was found to be located 75m to 150m to the east of what was the expected location based on regional mapping. The anomalies are open to the south but increasing infrastructure in that direction makes the area less attractive for exploration.

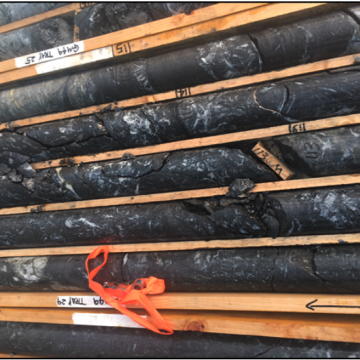

During 2018, a two phase 37-hole (3173.8m) Diamond drill program was undertaken at the Geumam Project comprises of relatively shallow holes ranging from 40m to a maximum of 144.7m. The first phase (15 drillholes/ 1,471.4m) completed by early June. The second phase of the drilling targeted several zones identified by mapping and channel sampling as well as a number of zones highlighted by the IP survey results

Property scale potential to extend Resource through systematic drilling/sampling of targets defined to date.

Historical Background

Geumam is reported to have been in production between 1985 and 1992 with remnants of a small processing plant still in place on site. The plant consisted of a ROM stockpile, conveyor, feed hopper, ball mill, two flotation cells and a regrind ball mill.

Initially, the plant throughput was 6tpd fine flake Graphite flotation concentrate grading 85% Graphite (Cg) (51% of 150-45μm product and 49% of -45μm product). The plant was upgraded with an alkali leach plant capable of producing high-grade fine flake graphite concentrate (93-97% Graphite (Cg).

In 1987, 791.7 tonnes of graphite were produced, with 169.5 tonnes produced in the first three months of 1988. The product was flaky Graphite with a fixed carbon content of 96% and 100% passing 12 microns.

Historical metallurgical reports from KMPC indicate from a ROM head grade of 7 5% Graphite (Cg), a flotation concentrate grading 87.6% Cg was produced after 2 cleaner flotation cycles, with a recovery of 79. 2%. Recovered graphite flake distribution is tabulated below, indicating 30% of the flake is high value large and coarse flake product.

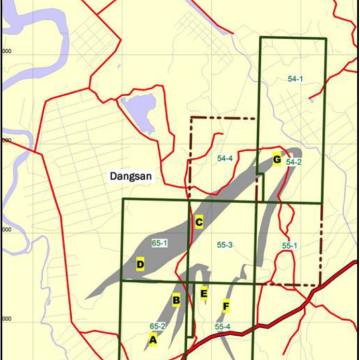

Historic mining and sporadic exploration consisting of geological mapping, rock sampling, auger sampling, channel sampling, geophysical surveys and diamond drilling have defined 7 target zones (A-G).

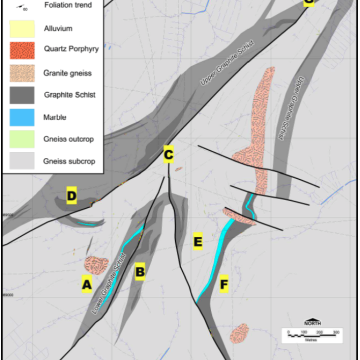

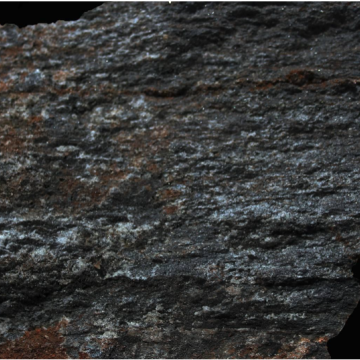

Geology & Mineralization

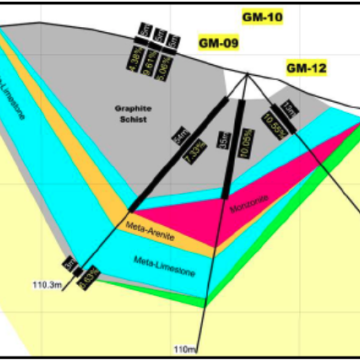

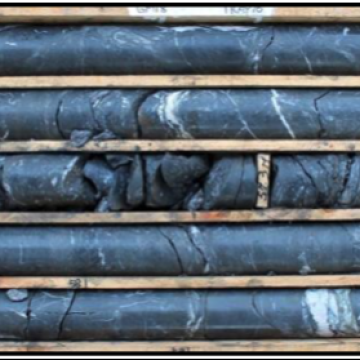

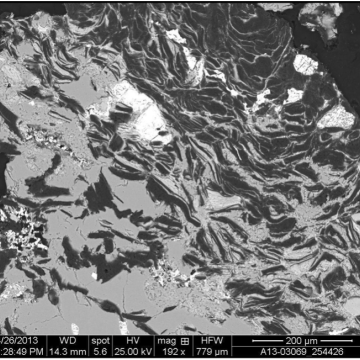

Deposits are flake Graphite hosted in graphitic schist. Graphite tends to form as malleable bodies, easily subject to faulting and folding. The graphite schist is interpreted to have originally been thin-bedded, carbonaceous, feldspathic, medium-grained quartz sandstone and mudstone. The precursor to Graphite could have been biogenic material that concentrated in a trough depression onto the thin limestone platform, under reducing conditions.

Massive graphitic-quartz veins and breccias are clearly associated with major fault structures that control the current distribution of graphite schist. This intimate Graphite-quartz association suggests the original carbon may have been introduced during hydrothermal activity along the fault structures and deposited into an adjacent restricted trough. The original carbon source for the Graphite is uncertain, however site geologists postulate carbon was introduced in primitive bituminous hydrocarbon form.

The geological setting and characteristics at Geumam point towards the presence of a submarine hydrothermal system related to contemporaneous granitic igneous intrusive activity during deposition of the graphite schist. The granite gneiss is broadly stratiform and conformable with interpreted sedimentary bedding and is interpreted as a sill or extruded onto the submarine seafloor.

Current Exploration

BMR in 2018 completed a 10-line IP (Indcued Polarization) survey that encompassed an area from the Target D in the southwest through Targets “B-C-E & F” in the central part of the zone and extending about 400m northeast of target G on the morthwest end of the known mineralized zone.

The survey clearly identified several new areas as potential Graphite zones. The IP extended the potential strike length of Graphite in Targets B & E, identified IP anomalies in Target G, found IP anomalies at mapped Graphite horizons over a strike length of about 900m, outlined strong anomalies along strike in Target C, & identified a new trend 75m - 150m to the east of Target F.

- Best mineralisation hosted in Zones B and Zone E.

- Zone G appears more prospective than Zone F.

- The western side of Zone B has potential for shallow high-grade graphite

Low resistivity anomalies were identified under colluvium in the area between Zones B and E. The survey also extended the potential strike length of Graphite at Targets B and E. Significant IP responses were identified at Target G. The anomalous responses mostly coincide with recently mapped graphite horizons and extend over a strike length of about 900m. At Target C the survey outlined stronger anomalies along strike from the current focus of attention. To the southeast at Target F; a potential Graphitic trend was found to be located 75m to 150m to the east of what was the expected location based on regional mapping. The anomalies are open to the south but increasing infrastructure in that direction makes the area less attractive for exploration.

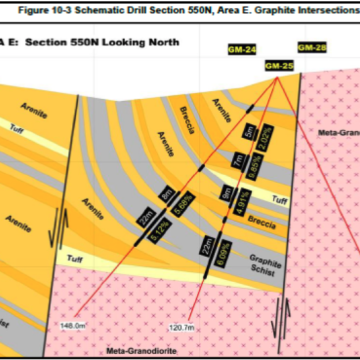

During 2018, a two phase 37-hole (3173.8m) diamond drill program was undertaken at the Geumam project comprises of relatively shallow holes ranging from 40m to a maximum of 144.7m. The first phase (15 drillholes/ 1,471.4m) completed by early June.

This drilling was focussed on the Target B & E areas and consisted of a series of infill drillholes to better define the known mineralised zones. This infill drilling targeted a 200m wide gap within the link zone between the northern parts of Targets B and E as well as the hill to the west of the Target B drillholes where recent mapping confirmed there is virtually no outcrop, but it appears that the Graphite bearing horizon caps the hills as a folded shadow dipping body.

The second phase of the drilling targeted several zones identified by mapping and channel sampling as well as IP resistivity low anomalies.

Property scale potential to extend Resource through systematic drilling/sampling of targets defined to date.

Current Resource & Metallurgy

Indicated Resource: 2.6Mt @ 6.6% Graphite for 101,000 Tonnes Contained Graphite and 5.6Mt @5.5% Graphite for 306.000 tonnes contained Graphite

The drillhole spacing for the project is irregular and varies from approximately 100m by 25m in the well-defined areas of the project to 120m by 50m over the remaining areas.

The mineralisation trend shows good continuity of the main mineralised zone allowing the drill hole intersections to be modelled into coherent wireframes.

A Surpac block model was created to encompass the full extent of the deposit. The block model used a primary block size of 50m NS by 10m EW by 5m vertical with sub-cells of 6.25m by 1.25m by 0.625m.

The parent North-South block size was selected on the basis of 50% of the average drillhole spacing of the project, while dimensions in other directions were selected to provide sufficient resolution to the block model in the across-strike and down-dip direction.

Grades were estimated using Ordinary Kriging.

For all zones in the Geumam project, the wireframe lodes were used as hard boundaries in the interpolation. That is, only grades inside each object were used to interpolate the blocks inside the object.

Preliminary Metallurgical Testwork completed BMR is summarized below:

- Based on a crush size of 850μm, MLA analysis has determined the average in situ graphite flake size of 102μm at Area B and 75μm at Area C.

- Likely separation flowsheet is based on flotation, with regrinding of the cleaner concentrates to produce a 85% Cg graphite concentrate.

- Comminution studies have concluded that the ore types ranged from soft to moderate hardness and would present no difficulties in milling.

- Separation testwork has finalised the optimum grinding and flotation roughing conditions with optimum grind size is moderately coarse at 80% passing 212μm for the Area B deposit and slightly finer at 80% passing 180μm for Area C.

- Very high purity graphite concentrates would be prepared by leaching of the final flotation concentrates to remove any relict gangue minerals

Geumam Graphite Deposit 2018 NI 43-101 Mineral Resource Estimate

(RPM Global (RPM Advisory Services Pty Ltd.) March 2018)